Monthly Archives: April 2010

Should Have Posted a “Caution: Don’t Knock Our House Down” Sign?

I saw this on the national cable news two nights ago, the horrifying story of a Denton TX woman whose house was basically destroyed...

St. Boniface Hospital’s Lean Journey: Enhancing Patient Care and Efficiency

The Winnipeg Free Press has an article about their local St. Boniface Hospital, a member of the LEI/ThedaCare network I'm involved with called the...

The Waste of Pulling Promised Training Funds in Rhode Island

I'm sharing this appeal on behalf of a good Lean friend, Karl Wadensten from VIBCO in Rhode Island.

Karl is fired up, rightfully so, because...

Follow Ups from @ericries #leanstartup Webinar

Thanks to Eric Ries for an outstanding webinar today for LEI, "Lessons from Lean Startups." We had over 1300 registrants from over 60 countries,...

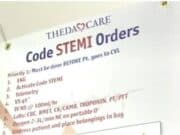

Read this Book – But Don’t Copy ThedaCare

Due out in June is a book that I think will be an important one for the Lean Healthcare movement. That book is about...

How I Broke My Blog and Fixed It… Lessons Learned

For those of you who have had difficulty accessing LeanBlog.org for the past two weeks or so, I apologize. It's been frustrating to me...

Eric Ries and Lean Startups in the NY Times

Looking ahead to Wednesday's free LEI webinar "Lessons from Lean Startups" with Eric Ries, it's exciting to see Eric and Steve Blank featured in...

Liveblogging the Quaid Patient Safety Documentary

I'm blogging notes and thoughts as I watch the Discovery Channel documentary by actor Dennis Quaid and others -- "Chasing Zero: Winning the...

Parallels between “Lean Startups” and “Adaptive Design”

I've been a fan of the "Lean Startups" work of Eric Ries since last year, so I'm happy to be producing a free LEI...

Retaining Employees through Respect and Development

I was recently in Toronto and I heard a story on an AM news station that really caught my ear. I have searched on...

Lean is “Taking Canadian Healthcare by Storm,” but Look Out for “L.A.M.E.”

In an article ("Assembly required: Health care from the Toyota factory floor") from Canada's National Post newspaper says Lean healthcare is "taking Canadian healthcare...

Dennis Quaid and Patient Safety – Upcoming Documentary

You might be familiar with the case where the actor Dennis Quaid's twins were harmed by an overdose at the famed Cedar-Sinai Hospital in...

![When Was the Last Time a Leader Around You Admitted They Were Wrong? [Poll]](https://www.leanblog.org/wp-content/uploads/2025/07/Lean-Blog-Post-Cover-Image-2025-07-01T212509.843-100x75.jpg)