Frank and Lillian Gilbreth: scientific management in the operating room

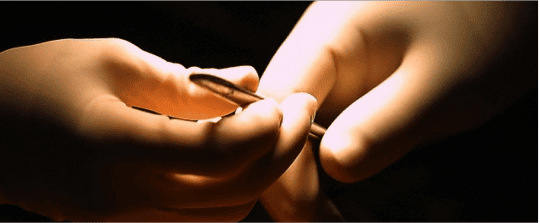

I sprung $20 for this healthcare journal article about the Gilbreths, thought I'd share a few historical tidbits here. I already knew that Frank Gilbreth was credited with the idea that surgeons shouldn't waste time digging around looking for their own tools — they needed what Gilbreth called a “surgical caddy” to hand the instruments to them.

That created the familiar cliche' scene on TV and movies of the surgeon putting out their hand and barking “scalpel!!” and getting the instrument almost immediately.

Before this innovation:

“The Gilbreths observed that surgeons spent more time searching for their instruments when operating than actually performing the operation.”

Now there's a familiar theme in healthcare – often times nurses spend more time on a shift walking and searching for supplies, equipment, information, and medication than they spend on actual bedside patient care. This is something Henry Ford discovered in the 1920's and it's a problem today in 2009 in many hospitals (and some are fixing that problem with Lean methods).

The old story gives me a bit of pride as an Industrial Engineer, that engineers have been making a contribution to healthcare process improvement for a long time… well, trying to make an improvement.

What the journal article described was this disturbing detail:

“Gilbreth presented their results on surgical operations and the standarisation of techniques in operating rooms at the meeting of the American Medical Association in 1915. Their recommendations were first ignored by the medical establishment. In 1930, the AMA eventually accepted the Gilbreth's operating room procedures, recognising the value of motion study.”

Why that 15 year delay? I'm not sure if that will prove reassuring in the least to those of you who have great ideas that aren't being implemented widely enough (like Dr. Pronovost's brilliant checklists).

The article also kicks ole' Frederick Taylor, contrasting his approach to the Gilbreths'. While the Gilbreths arguably had a more humane approach, Taylor's approach to improvement treated the workers like this:

“One worker was carefully selected and asked to change the way he worked by following the engineer's directions exactly. ‘We want no back talk… When he tells you to walk, you walk, when he tells you to sit down, you sit down.”

Taylor famously improved productivity, but did so in a way that didn't come close to the Toyota principle of “Respect for People.” We're still teaching some managers and engineers to quit separating thinking from doing in the workplace… that everybody must be thinking and must be a process improvement person in the scope of their own work.

What do you think? Please scroll down (or click) to post a comment. Or please share the post with your thoughts on LinkedIn – and follow me or connect with me there.

Did you like this post? Make sure you don't miss a post or podcast — Subscribe to get notified about posts via email daily or weekly.

Check out my latest book, The Mistakes That Make Us: Cultivating a Culture of Learning and Innovation:

I think it was Brent James who said that it takes 18 years for proven best practice to become the industry standard in healthcare.

Be sure to see this recent NYT article about Dr. Brent James:LINK

[…] As I’ve blogged about before, it took 15 years for the American Medical Association to officially endorse an idea formally proposed in 1915 by Frank Gilbreth, an early industrial engineer. Gilbreth observed that surgeons spent more time searching for instruments than they did performing surgery, so Gilbreth suggested a “surgical caddy” who would keep instruments organized and hand them to the surgeon as needed. We’d take that for granted today. […]