As Patient Safety Awareness Week continues, thanks to all of you who shared this PBS News Hour story with me via email or Twitter. If you ever see something you think might be of interest, please let me know.

On March 9, this story aired on PBS: After tragic mistake, rural hospital transforms into model of success.

Tragedy and Death

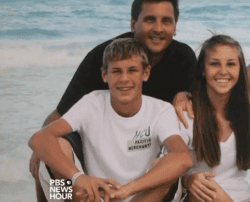

The piece starts with a tragic story, where Hill County Memorial, in Fredericksburg, Texas (west of Austin), misdiagnosed a 13-year old who had suffered a stroke. The “inattentive and callous” emergency physician didn't listen to the boy's mother about something not being right with Quinn Kott (pictured, at left).

Rather than just blaming an individual, it makes me wonder about the circumstances… was the ED overwhelmed with patients and, if so, was that something that could have been solved with Lean and process improvement strategies? How could we look at this in a way other than just blaming the individual? Was it a bad apple or a bad system? It's usually not a problem with “bad apples” in healthcare…

Sherul Kott, Quinn's mother, said in the story:

“I met the doctor coming down the hall, and I said, ‘Something is wrong with Quinn.' And he shushed me,” Sherul Kott recalled. “And I said, ‘No, don't you tell me to shush. You're the doctor. I'm the mom. There's something wrong with my son and I need to know what's wrong with my son, and we are not taking him home.'”

This episode reminds me of Sorrel King, who said physicians didn't listen to her… which contributed to the death of her daughter, Josie (listen to my podcast with Sorrel).

“It wasn't until the next morning that a pediatrician finally examined Quinn. He was rushed to a hospital in San Antonio, about 70 miles south, and died soon after. He had suffered a massive stroke.”

This incident was a wake up call for the hospital. Dr. Michael Williams, CEO at the time said:

“We had a clear opportunity to either do what most hospitals do and what we had done previously, which was get our attorneys involved, be prepared for a lawsuit,” Williams said. “Or we could take a different approach and work directly, reach out to the family and ask them to partner with us in really transforming the hospital.”

The hospital needed transformation, as they were:

- Losing money each year

- Patient satisfaction was “very low”

- Employee satisfaction was “very low”

- And people were “leaving the community to get their care elsewhere”

Listen to Mark read this post (subscribe to the series):

On the topic of parents questioning things or parents catching mistakes, check out this recent story: “Mom and dad often catch hospital errors doctors missed.”

“Roughly one in ten parents spotted mistakes that physicians did not, according to the study of safety incidents observed on two pediatrics units at a hospital in Boston… For the subset of cases that were medical mistakes, the reviewers found 30 percent of the incidents caused harm and were preventable… Preventable errors described by parents included delays detecting a foreign body left behind after a procedure, recognition and treatment of urinary retention, and receipt of pain medication.”

That's one reason why the Batz Patient Safety Foundation also has a version of their Batz Guide for pediatric care (but I can't find it on their website). With all of these errors, children and adults alike need an advocate looking out for them and checking for errors.

Lean and Toyota

The Fredericksburg hospital hired a former Toyota employee, Jeff Darnaby to “help bring the car company's revered assembly line principles to Hill Country Memorial.”

Reading that quote, I have to comment that Lean and TPS isn't about “assembly line principles.” It's about:

- Management principles

- Problem solving principles

- Employee engagement methods

It's not just about assembly lines and Lean isn't about turning the hospital into an assembly line.

As Darnaby says:

“The Toyota production system basically allows you to identify waste, and remove that waste from your processes,” Darnaby said. “Anything that doesn't add value to the customer, to the process, is considered waste.”

The hospital has also incorporated other outside ideas from Southwest Airlines and Ritz Carlton hotels.

Here is the video:

In the story, you can see some glimpses of the Lean / Toyota methodology, as I had shared on Twitter:

I'm surprised that “Finance & Growth” was listed first. Usually, Toyota and Lean organizations list cost or finance last, with safety and quality first… since cost is the end result of improving safety and quality.

Hill County Memorial was won the prestigious Malcolm Baldrige National Quality Award:

There are many problems in healthcare and far too much harm to patients… but I congratulate Hill County Memorial and wish them the best in the rest of their “Lean journey.”

What do you think? Please scroll down (or click) to post a comment. Or please share the post with your thoughts on LinkedIn – and follow me or connect with me there.

Did you like this post? Make sure you don't miss a post or podcast — Subscribe to get notified about posts via email daily or weekly.

Check out my latest book, The Mistakes That Make Us: Cultivating a Culture of Learning and Innovation:

As scary as that sounds, I can see how that stroke diagnosis could easily be missed, even in the best of circumstances. A 13-yr old coming in with slurred speech, limb weakness, etc isn’t typical for stroke patients. So many other more likely causes. When I was 27, I had severe lower back pain. Initially diagnosed as herniated disk / thoracic nerve entrapment. Took 6 months for them to finally realize it was actually gall stones. Just wasn’t a typical for a male in his mid-20s. ED docs have minutes to diagnose a wide range of symptoms. Occams Razor usually holds true, but sometimes it doesn’t.

But kudos to Hill County. I’m more impressed with their clinical outcomes than their more straightforward waste reduction. Most hospitals embarking on their lean journey struggle to really drive clinical performance in any significant way, but Hill County’s work is impressive. 90th percentile or better in 3 of 4 readmits metrics, solid in serious complication measures, 99th percentile for 3 of 4 HAC measures, massive improvement in HCAHPS. They’re definitely doing something right.