Hopefully you've already seen the famed 1980 NBC documentary “If Japan Can, Why Can't We?” that featured Dr. W. Edwards Deming. I posted a link to the video and some notes on Part 1 of the broadcast. Today, I'd like to blog about Part 3 of the program.

Coming Monday: Podcast episode #238 will be a discussion with Kevin Cahill, a grandson of Dr. Deming.

To set context for the times, supermarket bar code scanners were still a very new technology, as shown at the 47:00 of the program. The old fashioned cash register is “outdated” and “customers don't want to waste time in line” because the new technology is “faster,” although customers “have to get used to it.”

At about 50:00 into the video, the auto supplier Donnelly (now part of Magna) is featured. “The plant is organized into teams to figure out better ways to do the work and everybody gets a share of any productivity profits.”

The company president held a monthly meeting where “almost anything can be discussed… nobody feels left out or ignored.”

Donnelly workers brought forward ideas to improve productivity, but they are reassigned instead of jobs being lost. They emphasized employee participation and input… an employee, pictured below, says:

“Any kind of wild idea… bring them up! They will look into it and if it's possible, they will make it work.”

Even GM factories are discussed as examples of companies taking input from production workers, if you can believe it.

There's one interesting idea that I've never heard before… a relatively young company (at the time) in Seattle, Romac Industries (still around today) has production employees, like the guy pictured below, individually propose that they deserve a raise and this gets voted on by the people they work with. The people working in the factory know more about you than your managers, one employee said.

One other “go to Gemba” type detail from Romac:

“Once a year, every officer of the company must spend a day working in the shop… so no official forgets where the profits come from.”

At about 57:30 into the video, GM's “Quality of work life” or “democracy in the working place” approach is featured.

“It's people oriented… it's human.” GM learned, as Dr. Deming taught, that increased quality leads to increased productivity.

These GM plants had “Employee circles… not unlike the Japanese quality circles to talk about ways to do their jobs better and make it easier for everyone else… or more pleasant.”

“Quality circles” are still very present in Japanese companies today, as I've blogged about.

The most impressive effort at GM was their Tarrytown plant (closed in 1996). In 1970, the plant had the worst labor relations and production records of any GM assembly plant. Instead of closing it, they instituted the QWL program, which took a lot of patience and hard work, as the program points out.

In one very poignant scene (blogged about already by Dan Markovitz), a production worker, pictured below, from GM says:

“QWL is involvement, involving me in the decision making process and treating me as somebody. I wanna be somebody.”

See this 1979 HBR article about the lessons of QWL and Tarrytown.

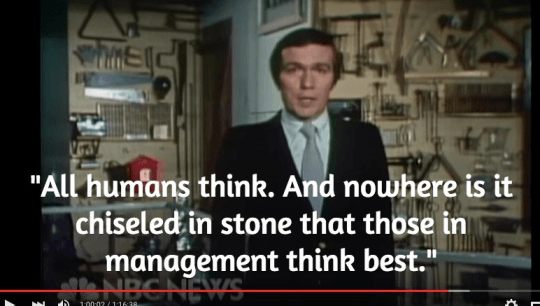

As host Lloyd Dobbins says at the end of the segment:

“No solution can succeed fully unless it includes the active participation of the people who actually do the work, union or non-union. All humans think. And nowhere is it chiseled in stone that those in management think best.”

Powerful stuff. Coming soon… a blog post about Part 4 of the video, which very heavily features Dr. Deming.

Also coming soon is my podcast interview with Kevin Cahill, one of Dr. Deming's grandsons who is active in the Deming Institute.

What do you think? Please scroll down (or click) to post a comment. Or please share the post with your thoughts on LinkedIn – and follow me or connect with me there.

Did you like this post? Make sure you don't miss a post or podcast — Subscribe to get notified about posts via email daily or weekly.

Check out my latest book, The Mistakes That Make Us: Cultivating a Culture of Learning and Innovation:

![Marcia Daszko on Leadership Lessons from Dr. Deming; Pivot Disrupt Transform [Podcast]](https://www.leanblog.org/wp-content/uploads/2024/03/lean-blog-501-marcia-daszko-238x178.webp)

[…] Yesterday, I shared some more notes from Part 3 of the 1980 NBC documentary “If Japan, Why Can’t We?” that featured W. Edwards Deming. […]

Been a long time, Mark. Nice to connect with your writing again. Sad fate for the Donnelly plant in Holland, MI. Despite having been featured in early Lean works as a great success story and nominated for a Honda supplier award the year before being sold to Magna the new owners closed it and moved the production to Mexico.

Thanks, Mark.

Sad to hear about that. It goes to show that Lean production alone doesn’t guarantee survival, not without the same management mindsets. A Deming company (or a Lean company) would stay close to their customer instead of chasing cheap labor.